I love woodworking tools, especially those used for making miniatures. The Dremel tablesaw was for many years the only realistic option available for making dollhouse items and for ship modeling and model railroad work. While there are now other saws around such as the Proxxon, Microlux and Byrnes table saws these older Dremel Tablesaws are still useful and are the more affordable option. There is no manual around for maintaining them, tuning them up, alignment and such so I have undertaken to help with showing everyone how to do it on my blog. I am currently downsizing my workshop so I have a couple of these saws for sale. Contact me by email by sending to karincorbin at gmail.

On the saw shown here I only needed to do some relatively minor work to put it back into prime operating condition. Over the years I have had opportunity to have purchased or been gifted several of the Dremel 580 table saws as well as the same saw with a Sears Craftsman label on it. This is one of those saws, it was basically unused because the belt kept slipping off the pulley.

The top surface look slightly scuffed but still in good shape. I turned on the saw and the motor sounded just fine, really fine in fact. Unplugged it and flipped the saw over so I could get a good look inside. Oh now that is strange was my first thought, what in the world is a C-clamp doing in there. Then within seconds my brain clicked out the answer, the belt was slipping. That is a very common problem with the Dremel Table Saw and frustrates many people. However it is a fairly easy fix....if you know how. So I am showing you how in this posting.

Now another thing I noticed is a bunch of rust on some of the metal. Don't get upset about it if you see that on a used saw because I have rarely seen a Dremel Saw that did not have it. They did not coat those particular parts with a decent protective finish. This is also a fairly easy fix. After you take care of the rust remember that it will occur again if you don't do some routine preventative maintenance on your saw.

The truly great thing I noticed about this particular Dremel Table Saw is that it has never cut so much as one inch of wood or anything else. There was not one speck of sawdust in the dust shoot or under the saw, only a few some cobwebs. It belonged to the aunt of the guy who sold it to me. She must have turned it on, had the belt slip then tried the C-clamp fix which of course did not work. I knew it was a keeper, a 20+ year old virgin Dremel table saw. Believe it or not I found another one of these virgins a few months ago and it was still in the box.

I sprayed the rust with "Rust Free" a product from Boeshield. This product is phosphoric acid, you can get similar products at auto parts stores. I let it sit for a minute or two then scrubbed with a soft brass bristle brush that is the size of a toothbrush. Cleaned off the part and let it dry. Phosporic acid converts rust, not sure what it converts it to but those little remaining spots where rust used to live are now black colored and have a protective coating on them. After I cleaned up all those rust prone parts I coated them with another Boeshield product, T-9. That stuff is so much better than WD-40 it is not even in the same class. It will protect the parts for a long time. I also used it to treat the threaded shaft that raises and lowers the blade as it was not turning as freely as I would have liked. Just a couple of squirts and that problem went away too. A dry lubricant stick is also good to rub onto the threads. Lubricating the screw shaft should be part of your maintenance routine.

Fixing the belt that was slipping sideways proved to be a little more trouble. There is a set screw in each of the two pulleys. On this particular saw screws were so firmly screwed in I could not back the screw out by hand with a screw driver. Whatever you do don't strip those slotted screw slots trying to get them out. I took out my battery operated Makita impact screw driver. I love that driver, it fits my female sized hands and is so fine tuned that it will do delicate work but the impact ability also means it can break loose a frozen screw without stripping it. When removing this set screw be sure to use your hand to firmly support the pulley from behind, you don't want to bend any shafts or put stress on the main castings of the table saw.

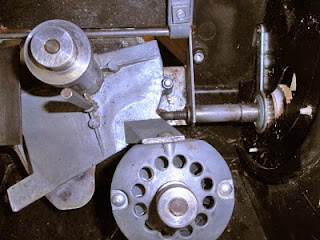

To adjust the tension on the belt you need to loosen the two screws that hold the motor to the table saw with an 1/8" allen wrench. You can see me doing this in the photo. If you go to www.micromark.com and type in Dremel table saw belt you will replacement belts you can order plus they provide a pdf file discussing replacing the belt and tensioning the belt. If adjusting the pulleys has not solved the problem you can try very slightly skewing the motor on the two mounting screws. You don't want to do an extreme side to side tilt as it is important the pulleys be aligned. A very minor tweak might do the trick, but only as a last resort if moving the pulleys in and out on the shaft did not fix the problem of belt alignment and slipping. There is one more method of getting the belt aligned if this method failed so keep on reading a bit further as I am showing it a little further down after this next photo.

When all the other attempts to get the belt from moving sideways towards the outside edge of the pulley has failed it is time to try putting in a shim. I have had a couple of Dremel Saws where for some reason there does not seem to be a true parallel between the shaft in the motor and the shaft that holds the saw blade. By putting a very thin shim between the pulley end of the motor mount bracket and the saw motor I have been able to correct the issue. In this photo I have used scissors to cut a piece of .002 inch thick piece of soft sheet brass and punched a hole in it to clear the screw. To punch the hole I used my notebook paper hole punch. So no exotic tools needed for this task. Thin brass is available at hardware stores and also in craft stores. I stuck the shim in place with a piece of double sided tape, the thin stuff, clear stuff used for gift wrapping will do the trick. It is just to keep it from shifting on you while you put the screw back in and then tension the motor. Now my belt tracks true and stays right in the center. These two photos showing the shimming are from a different Dremel Saw than the one shown above. In this case I had just installed a brand new motor.

Next up...what I use to clean and lubricate the saws. This is part of a kit I keep in a tote for workshop maintenance task on my tools. You might also need one of the oil based rust loosen liquids to free up rusted screw threads.

This is my chemical arsenal, left to right

Boeshield T-9, lubricates and prevents rust

Boeshield Rust Free, helps loosen rust and coverts it to get rid of it

Boeshield Blade and Bit, removes loose rust, gummy old oil, caked sawdust, resins from saw blades, screw threads & machine parts

Bostik Dri-Cote, I spray this on saw blade and router bits to help prevent resin buildup and burning, makes cutting easier

Bostik Top-Coat, I spray the tops of my table saw, band saw, drill press, planer and other metal tools with this product. It keeps them cleaner, prevents stuff from sticking to the tops and makes everything slide freely across the surface. No Silicone in it and it won't mess up finishes on wood.

Bostik Bearing Lubricant, I use this on the bearing in router bits and on machine parts that need to slide or move freely.

Another problem that happens when you find a used Dremel tablesaw is that the very thin wrench that goes against the inside of the blade to hold the shaft still while you tighten on the nut has gone missing. The original tool for this task was made from a bent over piece of sheet metal with 3/4" notch in it. Seen below as illustrated in the manual.

Having trouble raising and lowering the blade? This next section is all about how to fix that issue.

There are several things or a combination of things that can create this situation. First photo below is just an overall view of underneath the saw to get you oriented for the rest of the photos.

So first lets talk about one issue and that is where you turn the adjustment knob on the front of the saw and nothing happens, the knob goes round and round and the blade does not move up and down. In the photo below take a look at the small tabs the red arrow is pointing to. They are meant to locate on the flat surfaces of the metal cylinder that houses the screw adjustment. If someone has tried to force raise the blade when the height adjustment is binding up on the screw they can spring open that detent area a little and with will spin around and end up on the curved surface of the cylinder instead of remaining in the proper location. To fix the problem turn the shaft so they are on the flat and using a flat bladed screw driver gently tap them back against the shaft so they grip once more.

In the photo above where the yellow arrow is pointing you can see how much dirt can get stuck in the adjustment screw over time. That needs to be cleaned off as part of your regular saw maintenance. Be sure to lubricate the threads with the Boeshield T-9. Don't use sticky grease for lubrication, it will trap the dirt on the screw and it will travel up into the cylinder get packed into it and cause binding. If your old saw has that condition you will need to spend a lot of time running the screw back and forth cleaning off the dirt it brings out of the cylinder. Eventually you will get it cleaned up. A soft brass wire brush can be used to remove excess rust from the screw. PB Blaster is also a good chemical product to loosen rust, but remove the belt before you apply a spray chemical. (You don't want the belt to absorb a lubricant as it could lead to belt slippage.) If you need to you can use a fine steel pick or even a toothpick in between the threads to remove stuck particles the brush does not take off.

I was recently asked if you can unscrew the black plastic knob on the front and take it off. I don't believe you can, I am pretty sure it was a press fit installation. There would be a real risk of damaging the plastic saw's housing if you tried to pry it off of the shaft. You can remove the metal saw housing by taking out the two screws that come in from the top surface and the screws that hold that metal housing to the plastic saw body. Then once the housing is loose start turning the black knob until the screw that raises and lowers the saw blade backs out of the shaft the knob is attached to. But you would not need to do that unless you really needed to do a major rust removal job on those screw threads and also chase the threads inside the shaft. Pretty much a last resort fix for the blade raising screw to get it freed of rust and working smoothly.

The final condition that can cause binding while raising the saw blade is found towards the back of the saw, see photo below. There is a cover plate with a curved slot. There is a bolt that goes through the slot. Dremel Tablesaws have metal that is prone to rust. Most people store their saws out in unheated garages and rust builds up on the inside surface of that cover where and binds up the movement when the saw blade is raised or lowered. Remove the bolt at the rear of the cover (see yellow arrow). Next loosen the bolt that is towards the front of the saw. Take a long piece of emery cloth and some rust removing oil and do your best to pull back and forth on the strip, scouring off that rust that is on the inside surface of the cover plate. Put some T-9 on that cleaned surface to lubricate and prevent more rust from forming. Put the bolt back and tighten the front and rear bolts. Tighten to barely snug then back the nut off very slightly as the parts must move freely and not bind.

____________________________________________________________________________

____________________________________________________________________________

It is important on any table saw that the blade is positioned parallel to the miter slots. See the photo below. There are two screws on this saw (see yellow arrows) used to make that adjustment. Unplug your saw before you begin. Back the screws out leaving one of them barely tight to uses as a pivot point but the other one looser. I use a ruler with fine calibration marks. It is best to choose one saw tooth to measure from. Mark it with tape or paint so you don't get confused. Put the tooth at the front of the saw and measure from the edge of the slot over to it, then rotate that tooth to the rear of the saw and measure from the edge of the slot over to it. The measurement should be the same. After you have made this adjustment and go on to adjust the fence remember that the distance between the saw blade and the fence must NEVER be smaller at the back edge of the saw blade than at the front or you will create a pinch point and get kickback where a board can come shooting out of the saw right back into your stomach.

Last but not least, replacement motors. I know of only one source for an authentic replacement motor. This company purchased the remaining stock of them. They are not inexpensive however they are the real thing, it is the OEM motor from the Emerson Motor Co. that your Dremel tablesaw came with when it was new. I do not recommend using an under powered sewing machine motor or the ones such as the one from Grainger that you will see posted elsewhere on the internet by people saying it is a proper replacement motor, it is not! The motor from Grainger is not a good substitute. Contact the company below, sometimes they list them on EBAY and they are shown in their company catalog. SH Goode and Sons also sells quality hardwood lumber such as Cherry cut to scale thickness sizes for making miniatures.

S.H. Goode & Sons Workshop

Steve & MaryAnna Goode

PO Box 2575

Atascadero, CA 93423

Voice: (805) 460-9663

Fax: (805) 460-0424

Steve & MaryAnna Goode

PO Box 2575

Atascadero, CA 93423

Voice: (805) 460-9663

Fax: (805) 460-0424